18V-50V DC brushless motor driver ZM-6515A+BL01 debugger 15A for brushless DC motor without Hall below 720W

18V-50V DC brushless motor driver ZM-6515A+BL01 debugger 15A for brushless DC motor without Hall below 720W

main feature

◆ It can be connected to an external speed display board to display the speed; it can also be connected to a computer to set the drive parameters

◆ Double closed-loop design of current and speed, large torque at low speed, stable operation;

◆ High torque and high speed output, the maximum speed can reach 10000rpm/min;

◆ Speed regulation mode: external PWM speed regulation, external potentiometer speed regulation;

◆ There are EN (enable), DIR (direction), X1 (brake) signal control terminals;

◆ It can output speed measurement pulse FG, (gate output);

◆ It can output alarm signal for user detection;

◆ With overcurrent, overvoltage, undervoltage, Hall sensor phase error, motor stall and other protection functions.

product description

ZM-6515A brushless DC motor driver is the latest high-tech product introduced by our company for the field of medium power motor drive. This product uses large-scale integrated circuits to replace the original hardware design, and has higher anti-interference and fast response performance. This product is suitable for driving any low-voltage three-phase brushless DC motor with or without Hall with a peak current below 15A and a power supply voltage within DC18V~50V (nominal panel DC24V~48V), and has high current operation. characteristics of low temperature. Products are used in a series of electrical automation control fields such as knitting equipment, medical equipment, food packaging machinery, and electric tools.

Functional Overview

This product can realize the following functions: (The standard factory default setting is square wave with Hall open loop mode)

1. Square wave has Hall speed open loop operation

2. Square wave has Hall speed closed-loop operation

3. Square wave open-loop operation without Hall speed

4. Square wave closed-loop operation without Hall speed

5. Constant torque open-loop mode operation (long-time overload operation is strictly prohibited)

6. Constant torque closed-loop mode operation (long-time overload operation is strictly prohibited)

Users can set the above functions according to the PC software or handheld debugger provided by our company.

Electrical performance index

Electrical performance (at ambient temperature Tj=25℃)

Power supply DC18V~50V DC power supply

(The capacity is selected according to the motor power)

The maximum input current is not more than 15A

(depending on the motor and rated load)

Input maximum power up to 720W

Adapted motor Adapted to the motor with output power ≤500W

Insulation resistance at room temperature > 500MΩ

Dielectric strength 0.5KV under normal temperature and pressure, 1 minute

Use environment parameters:

Cooling method Natural air cooling & forced air cooling

Use environment Occasion Try to avoid dust, oil mist and corrosive gas

Temperature 0℃~+50℃

Humidity <80%RH, no condensation, no frost

Vibration ﹤0.5G (4.9m/s2) 10Hz-60Hz (non-continuous operation)

Storage temperature -20℃~+65℃

Dimensions 150mmX97.5mmX53mm

Weight about 0.55Kg

【Note】Due to the drastic changes in the storage and transportation ambient temperature, condensation or frost is likely to occur. At this time, the driver should be placed for more than 12 hours, and the driver can be powered on and run after the temperature of the driver is consistent with the ambient temperature.

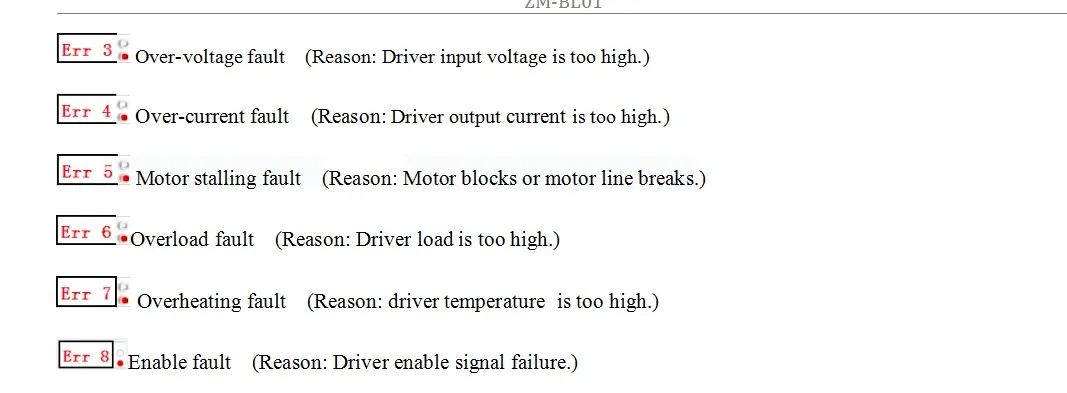

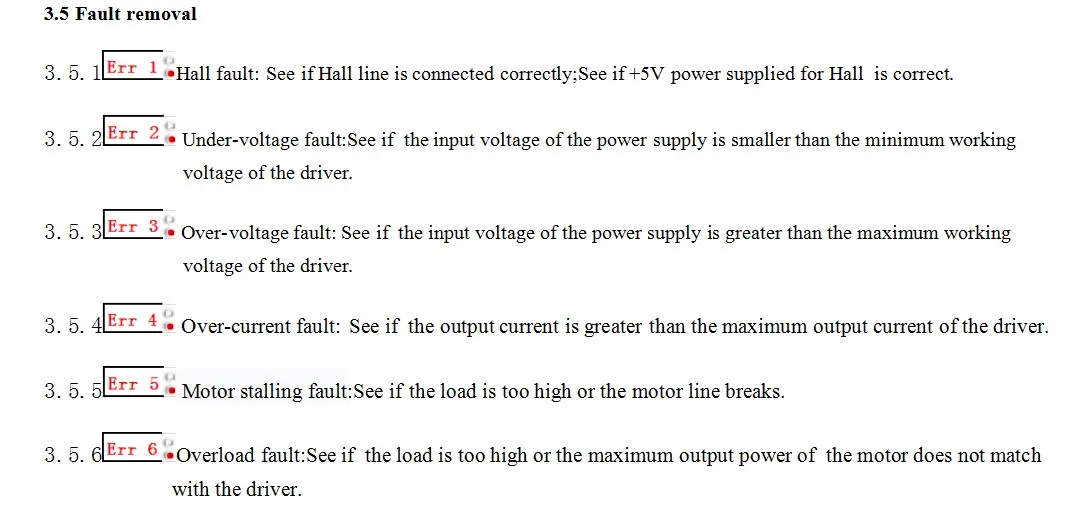

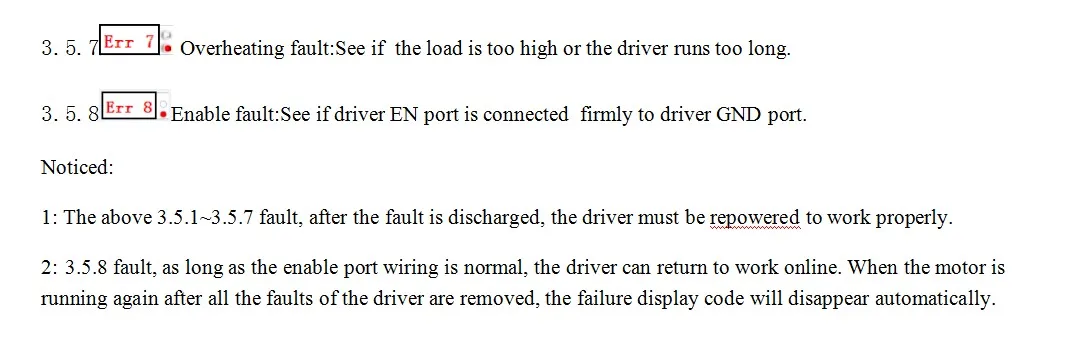

Indicator POWER Green power indicator, on when power is on, it means the power is normal

ALARM red status indicator

(1) The red light is off when it is normal;

(2) The red light is always on when EN is not connected to GND1;

(3) When the motor Hall fails, the red light flashes once and stops for 1s;

(4) When undervoltage (power supply voltage < 16V), the red light flashes for 2 times and stops for 1s;

(5) When overvoltage (power supply voltage > 56V), the red light flashes 3 times and stops for 1s;

(6) When overcurrent (power current > 15A), the red light flashes 4 times and stops for 1s;

(7) When the motor is locked, the red light flashes 5 times and stops for 1s;

(8) When the drive is overloaded, the red light flashes 6 times and stops for 1s;

(9) When the drive is overheated, the red light flashes 7 times and stops for 1s;

(10) When the phase current of the driver is too large, the red light flashes for 9 times and stops for 1s.

The RS232 communication port TTL can be connected to the ZM-BL01 handheld intelligent debugger to display the speed and can also be used to set the drive parameters. For details, please refer to the instruction manual of ZM-BL01 handheld intelligent debugger

Control signal terminal +5V1 Control signal power supply is positive (built-in power output)

VSP External speed control signal

Control method: 0~100% speed adjustment is realized by changing the voltage of VSP terminal through an external potentiometer, the range is 0~5V

X1 Motor brake control, X1 is not connected or connected to +5V1 The motor rotates normally, X1 is connected to GND1, the motor brakes to stop, the red light is always off

FG Motor speed pulse output, which can be converted into the actual speed of the motor by measuring the frequency of this signal

DIR Motor forward and reverse control, DIR is connected to GND1, the motor is reversed (counterclockwise); DIR is not connected or +5V1 is connected, the motor is forward (clockwise)

EN Motor enable control, EN is connected to GND1, the motor turns (online state); EN is not connected or +5V1 is connected, the motor does not turn (offline state), the red light is always on

ALM alarm output, ALM output high level 5V when working normally, ALM output low level 0V when there is a fault

GND1 Control signal power ground

+5V2 Motor Hall power supply is positive

HU Hall sensor signal U phase input

HV Hall sensor signal V-phase input

HW Hall sensor signal W-phase input

GND2 Motor Hall power ground

U, V, W motor three-phase output, connected to the motor winding

GND, V+ DC18V~50V power supply input. (Panel nominal DC24V~48V)

Function Description

Speed regulation mode selection (VSP) 1. The VSP port can be connected to an external potentiometer for speed regulation: connect the two fixed ends of the external potentiometer (5K~10K) to the GND1 and +5V1 ends of the driver respectively, and connect the adjustment end to the VSP end , you can use an external potentiometer to adjust the speed, or you can input an analog voltage to the VSP terminal through other control units (such as PLC, microcontroller, etc.) to achieve speed regulation (relative to GND1), and the VSP port accepts a range of DC 0V~+5V , the corresponding motor speed is 0~ rated speed;

2. The VSP port can input PWM signal for speed regulation: connect the positive end of the PWM signal to the VSP port and the negative end to GND1, and change the PWM duty cycle by setting a PWM signal with a frequency of 100Hz~100KHz and an amplitude of +5V to achieve speed regulation.

Speed measurement signal output (FG)

The driver provides the motor speed measurement pulse signal, which is proportional to the motor speed.

Speed calculation method: Motor speed (RPM) = F÷N×60

F = The frequency on the FG pin is actually measured with a frequency meter

N = number of motor pole pairs (2-pole motor N=2; 4-pole motor N=4)

For example, if the user chooses a 4-pole motor, then: when the output FG signal is 200Hz, the motor speed = 200÷4×60=3000 rpm.

Motor forward/reverse

Signal

(DIR) The forward and reverse rotation of the motor can be controlled by switching the high and low levels of the control terminal DIR.

Note: In order to avoid sudden commutation when the motor is running at a high speed, which will cause a huge impact on the motor and mechanical equipment, when the DIR terminal receives the commutation signal, the driver first decelerates the motor until it stops, and then the motor changes direction and accelerates to the set speed.

Motor start/stop signal (EN)

By controlling the conversion of high and low levels of terminal EN, the stop and operation of the motor can be controlled. When EN is at a low level, the motor runs normally; when EN is at a high level or not connected, the motor stops working, in a free state, and the red light is always on. When the start/stop terminal is used to control the motor to stop, the motor stops naturally. The law of motion is related to the inertia of the load. At this time, the input current of the driver is less than or equal to 30mA.

The factory setting is shorted between EN and GND1.

brake

(X1) By controlling the switching of high and low levels of terminal X1, the stop and running of the motor can be controlled. When X1 is low level, the motor brakes to stop running, and the red light is off when braking; when X1 is high level or not connected, the motor is allowed to run.

Dimensions (unit: mm)

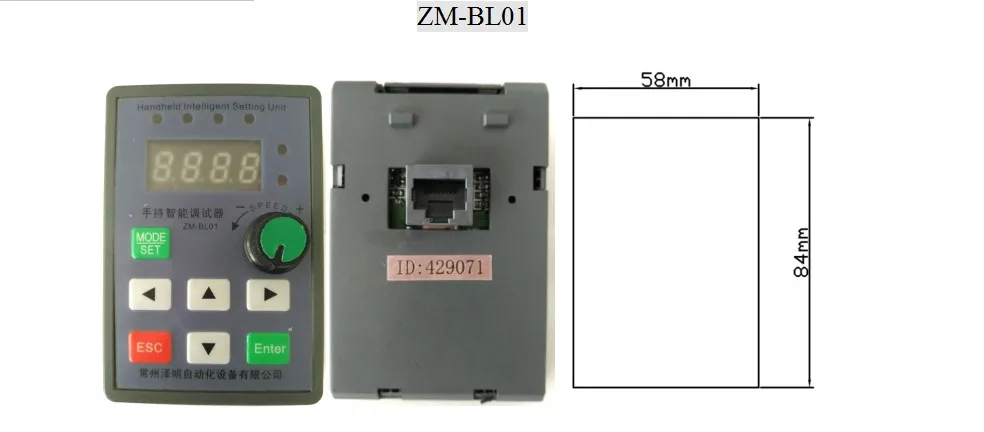

Handheld intelligent debugger is the newest product of our company, it is used to debug and set up our F series Brushless Motor Driver. So that ,all our F series divers can set up parameter by the network port of driver , and still can debug and set up by ZM-BL01.

1.connect: one of the phone line connect with driver’s pot, and the other connect with ZM-BL01’s pot, then finished2. run: press the potentiometer knob, four LED numbers(speed) will be shown on debugger , the range is 0-9999 turn/min,. when Brushless motor start to work, the real-time speed will show on the board of debugger.3.Stop: On the status of working, press the knob again, led do not light, the debugger stop working, it can be also used to emergency stop for the Brushless motor.

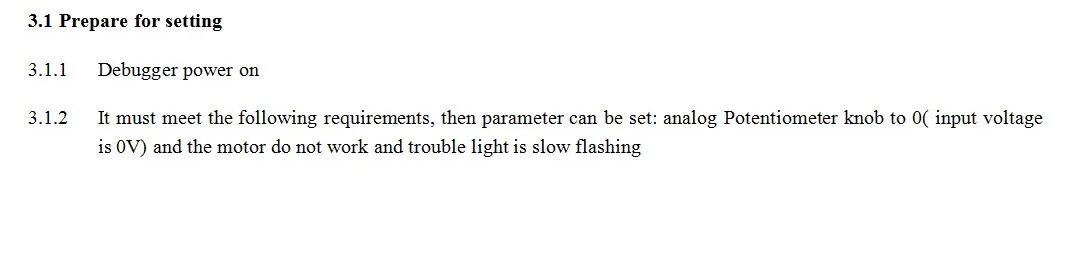

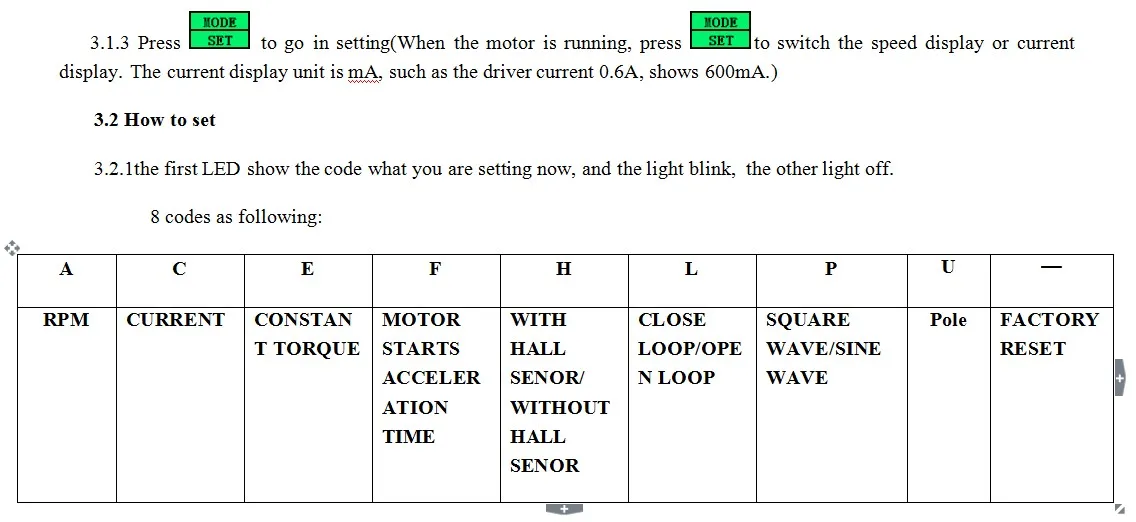

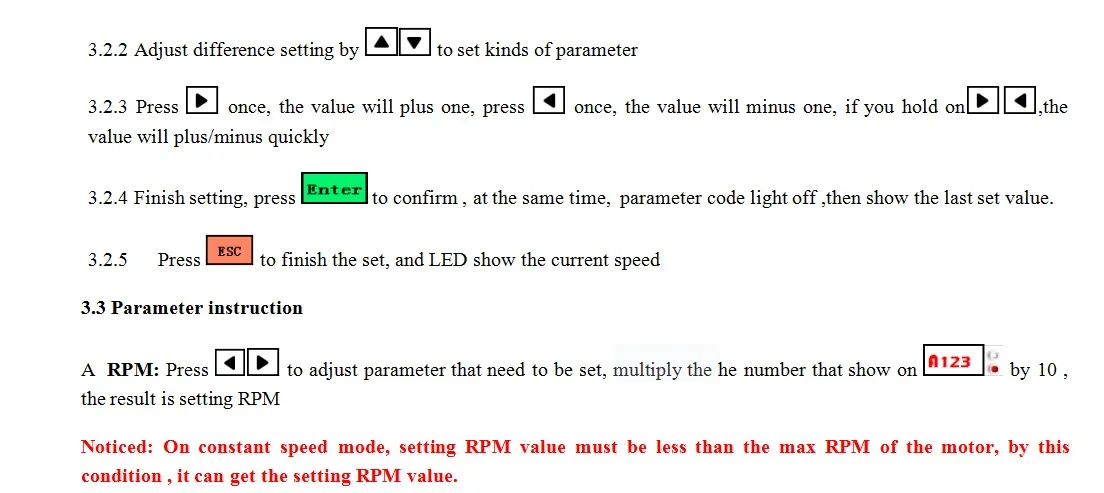

Parameter Setting

Origin : Mainland China

Motor Type : DC Motor